-

Rubber track undercarriage

-

Steel track undercarriage

-

GM radial piston Hydraulic Motor

-

A2FE high speed Hydraulic Motor

-

NHM Series Hydraulic Motor

-

GW series Hydraulic Winch

-

A2FM Series Hydraulic Motor

-

Orbital Hydraulic Motor

-

MS hydraulic motor (Poclain)

-

A6VM hydraulic motor

-

Small Hydraulic Winch (BG series)

-

GH series Hydraulic Winch

-

High Speed Hydraulic Winch (AF series)

-

Free Fall Hydraulic Winch

-

Recovery hydraulic winch

-

Planetary gearbox

-

Hydraulic Transmission

-

Track drive gearbox

-

Final drive gearbox (Rexroth GFT series)

-

Swing drive gearbox

-

Wheel drive gearbox

-

Winch Drive Gearbox GFT-W series

-

Catalogue

-

Hoist gearbox

-

QJM Series Hydraulic Motor

-

Dual displacement motor

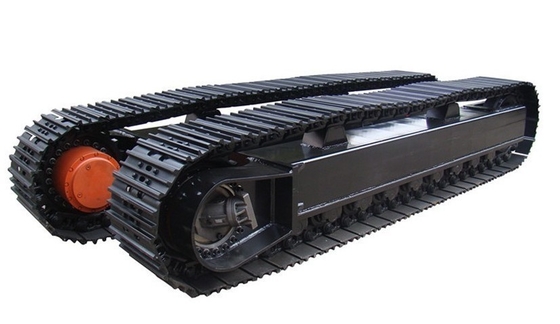

CRAWLER TRACK UNDERCARRIAGE ASSY

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Load Capacity | 1-100 Ton | Track Drive | Single Speed Or Dual Speed On Request |

|---|---|---|---|

| Material | Steel | Warranty | 1 Year |

| Application | Excavator,Crane,Bulldozer,Crusher,Drill Rig, Piling Rig | Condition | 100%new |

![]()

Crawler Track Undercarriage Assy manufacturer

Steel track undercarriage, Steel track frame, steel track chassis, steel track system, steel crawler undercarriage, steel tracked undercarriage, drilling rig steel track undercarriage, crusher steel trackundercarriage, excavator track undercarriage, Crawler Track Undercarriage Assy

Why to choose us?

We are the manufacturer and factory of Crawler Track Undercarriage Assy. We have experienced engineers with more than 10 years' experience in design and manufacturing different types of undercarriage for drilling rig, crusher, shredder, etc.

![]()

Specification of crawler track undercarriage assy:

7.Custom built: we can design and manufacture track undercarriage according to your specificdimension requirements.

Engineering machinery: min excavator, piling rig, aerail work platform; etc.

Mining machinery: mobile crushers, roadheaders, conveying equipment, etc.

Industrial equipment: sugarcane harvesters, lawn mowers, tumbling machines, shot blasting machines, etc.

If you have any question or need any help, please feel free to contact with us. Our service team is ready toprovide best service for you.

Specification

|

MODEL

|

Dinamic

capacity |

Static

capacity |

Weight

kg. |

Press.Bar

|

oil flow

L/min |

Torque

Nm to engine |

Grad.

|

Speed

km/h |

|

ST-3500

|

3500

|

4000

|

750

|

220

|

35

|

4723

|

65%

|

2/3.2

|

|

ST-6000

|

6000

|

7000

|

1350

|

220

|

55

|

8330

|

65%

|

2/3.7

|

|

ST-8000

|

8000

|

9500

|

1830

|

300

|

82

|

11700

|

65%

|

2.8/4.7

|

|

ST-10000

|

10000

|

11300

|

2350

|

350

|

100

|

14800

|

65%

|

3/5.1

|

|

ST-12000

|

12000

|

15000

|

2950

|

350

|

124 |

22500

|

65%

|

2.9/4.9

|

|

ST-15000

|

15000

|

18000

|

3300

|

350

|

140

|

24000

|

65%

|

3.2/5.5

|

|

ST-20000

|

20000

|

25000

|

4300

|

350

|

220

|

38000

|

65%

|

3.5/5.4

|

|

ST-30000

|

30000

|

37000

|

6500

|

330

|

260

|

59000

|

65%

|

2.5/4.6

|

|

ST-40000

|

40000

|

480000

|

7100

|

350

|

290

|

72800

|

65%

|

2.3/4.3

|

![]()

|

MODEL |

A

Length |

B

Center Distance |

C

Height |

D

Total Width |

E

Width of track shoe |

F

Height of Cross beam |

No. of

roller |

|

ST-3500

|

2030

|

1500 |

485

|

1800

|

300

|

225

|

4+4

|

|

ST-6000

|

2467

|

1950

|

549

|

1700

|

300-400

|

240

|

5+5

|

|

ST-8000

|

2783

|

2265

|

548

|

1800

|

400-450

|

255

|

8+8

|

|

ST-10000

|

3800

|

3200

|

600

|

1700

|

400-500

|

280

|

9+9

|

|

ST-12000

|

3282

|

2575

|

720

|

2000

|

400-600

|

345

|

9+9

|

|

ST-15000

|

3666

|

2923

|

753

|

2000

|

500-800

|

360

|

8+8

|

|

ST-20000

|

4065

|

3323

|

786

|

|

500-800

|

375

|

8+8

|

|

ST-30000

|

4530

|

3730

|

836

|

|

500-800

|

405

|

9+9

|

|

ST-40000

|

4888

|

4090

|

880

|

|

500-800

|

420

|

10+10

|

Frame connection type of steel track undercarriage

|

Bracketed Frame

|

A bracketed frame with machined plates provide a simple bolt on interface reducing assembly time. Standard bracketed models are available in many sizes. |

Weld-On Frame (Unbracketed)

|

A plain sided frame for your own connection method. This style can be incorporated into your chassis design allowing for the narrowest machine width. Our substantial frames allow a secure interface. |

Oscillating Frame

|

Oscillating frames, typically found on drilling rigs, precision manufactured to your specific requirements, or a collaboratively engineered solution. |

|

Cross Beam Track Systems

|

Our fabricated cross beam chassis design offers the customer the ultimate in assembly simplicity. This connection method allows the machine to simply be placed on top and fixed in place. |

Picture of undercarriage for reference

![]()

![]()

![]()

![]()

FAQ

1. Are you the manufacturer or trader?

We are the manufacturer with more than 20 years experience engaged in designing and manufacturing of undercarriage.

2. How long is the delivery?

Usually it is 20 days for the production.

3. What's the warranty of your product?

We can offer you 12 months quality guarantee period after receipt of product.

4. Can you custom make the product?

Yes, all dimensions and specifications can be designed and made based on your requirements.

5. How to order?

To make sure the offered undercarriage is suitable for your application, please offer the following details:

1. Rubber or steel track undercarriage:

2. What is the payload of undercarriage:

Note: it is the weight of machine excluding the weight of undercarriage.

3. length of track undercarriage (mm):

4. width of each side of track undercarriage (mm):

5. height of track undercarriage (mm):

6. total width of track undercarriage (mm):

7. working flow rate per each side of undercarriage (L/min):

8. working pressure (MPa):

9. travelling speed (km/hr):

10. climbing capacity:

Contact:

Welcome to contact us:

![]()